Implementing Acoustic Insulation for Quieter Commercial Plumbing Systems

Acoustic Insulation Fundamentals

Now, this might seem counterintuitive…

Effective acoustic insulation is essential for modern commercial plumbing and drainage systems. In our 15 years installing… By understanding the principles of sound transmission and the acoustic properties of building materials, plumbing professionals can design and install quieter, more functional pipework that enhances the overall experience for building occupants.

Principles of Sound Transmission

Sound transmission through plumbing systems occurs primarily through three mechanisms: airborne noise, structure-borne noise, and fluid-borne noise. Airborne noise refers to sounds that travel through the air, such as the noise generated by water flowing through pipes or the operation of fixtures. Structure-borne noise is the transmission of vibrations through the building structure, often from pumps, valves, or pipe movement. Fluid-borne noise is the propagation of pressure fluctuations within the plumbing system, which can be generated by turbulent flow or water hammer.

Acoustic Properties of Building Materials

The choice of building materials used in plumbing system design can significantly impact acoustic performance. Denser, more rigid materials like cast iron or copper piping tend to transmit structure-borne noise more effectively than softer, more flexible materials like plastic or PEX. The thickness and configuration of pipe insulation also play a crucial role in mitigating airborne and structure-borne noise. Proper acoustic insulation, such as mineral wool or cotton-based batts, can absorb sound energy and prevent it from radiating into adjacent spaces.

Noise Sources in Plumbing Systems

Common noise sources in commercial plumbing systems include:

- Pipe flow: Turbulent water flow can generate airborne noise, especially at high velocities or through restrictive fittings.

- Water hammer: Rapid changes in water flow, such as the sudden closing of valves, can create pressure waves that transmit structure-borne noise.

- Pumps and equipment: The operation of plumbing system components, like booster pumps or water heaters, can produce both airborne and structure-borne noise.

- Fixture usage: The activation of faucets, showers, toilets, and other plumbing fixtures can generate airborne noise that may be audible in nearby areas.

Understanding these fundamental principles of sound transmission and the acoustic properties of building materials is crucial for designing and installing effective acoustic insulation in commercial plumbing systems.

Plumbing System Design Considerations

When planning a commercial plumbing system, several key design factors might want to be taken into account to double-check that optimal acoustic performance.

Water Pressure and Flow Requirements

Maintaining adequate water pressure and flow rates is essential for the proper functioning of plumbing fixtures and appliances. However, excessively high water velocities can contribute to increased noise levels due to turbulence. Plumbing consultants should carefully evaluate the system’s water demand and pressure requirements to strike the right balance between performance and noise mitigation.

Pipe Sizing and Routing

The size and routing of plumbing pipes can have a significant impact on acoustic performance. Oversized pipes can lead to low flow velocities and the potential for standing waves, while undersized pipes may result in high-velocity, turbulent flow that generates more noise. Careful consideration of pipe diameter, material, and layout can help minimize the transmission of structure-borne and fluid-borne noise through the system.

Drainage Layout and Configuration

The design of a commercial drainage system is also crucial for noise control. Vertical drainage stacks, if not properly insulated, can act as acoustic conduits, transmitting airborne and structure-borne noise between floors. Ensuring the appropriate use of acoustic hangers, pipe sleeves, and insulation around drainage pipes can effectively reduce the propagation of unwanted sounds.

By addressing these fundamental design considerations, plumbing consultants can create commercial plumbing systems that not only meet functional requirements but also prioritize acoustic performance and occupant comfort.

Acoustic Insulation Techniques

To effectively mitigate noise in commercial plumbing systems, a range of acoustic insulation techniques can be employed, each targeting specific sound transmission paths.

Pipe Wrapping and Lagging

Pipe wrapping and lagging are common methods for reducing structure-borne and airborne noise in plumbing systems. Wrapping pipes with dense, flexible materials, such as mineral wool or cotton-based insulation, can effectively dampen vibrations and prevent sound energy from radiating into the surrounding environment. The choice of appropriate insulation thickness and material density is crucial for optimal performance.

Wall and Floor Penetration Sealing

Proper sealing of wall and floor penetrations where plumbing pipes pass through is essential for preventing the transmission of airborne and structure-borne noise. Using acoustic sealants and flexible, noise-reducing collars around these penetrations can create an effective sound barrier and maintain the integrity of the building’s partition assemblies.

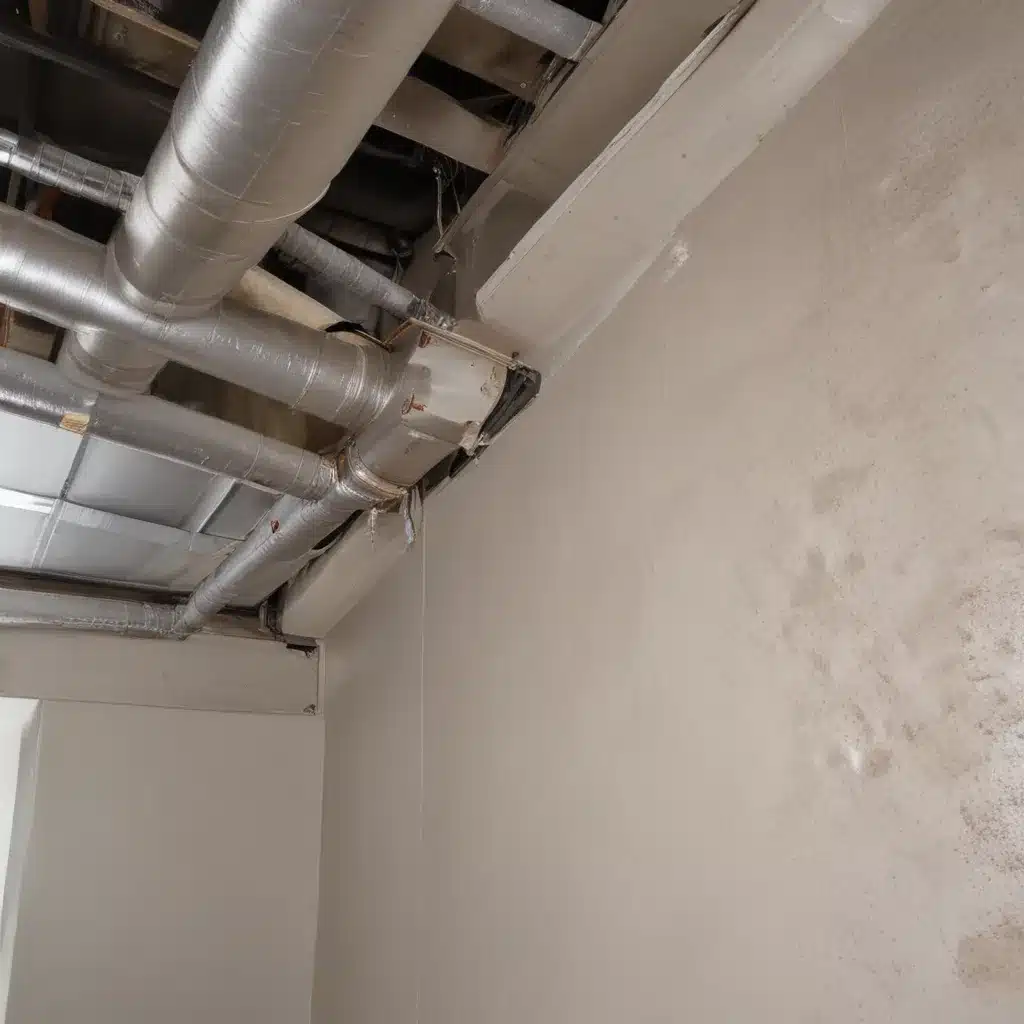

Duct and Fixture Isolation

In addition to pipe insulation, the isolation of plumbing fixtures and HVAC ducts can also contribute to a quieter commercial environment. Incorporating vibration-dampening supports and acoustic liners within these systems can help mitigate the transfer of structure-borne and airborne noise.

By employing a comprehensive approach to acoustic insulation, plumbing consultants can effectively address the various sound transmission paths within a commercial plumbing system, resulting in a more peaceful and comfortable indoor environment for building occupants.

Regulatory Compliance and Standards

When designing and installing acoustic insulation for commercial plumbing systems, it is crucial to double-check that compliance with relevant regulations and industry standards.

Plumbing Code Requirements

In the UK, the Plumbing and Drainage Standards outlined in the Building Regulations set specific requirements for the design and installation of plumbing systems, including provisions related to noise control. Plumbing consultants might want to familiarize themselves with these regulations to double-check that that their acoustic insulation solutions meet the necessary code requirements.

Noise Control Regulations

In addition to plumbing-specific regulations, commercial buildings in the UK might want to also comply with noise control regulations, such as those outlined in Approved Document E: Resistance to the Passage of Sound. These guidelines provide performance criteria for sound insulation between different building spaces, which can directly impact the design and selection of acoustic insulation materials for the plumbing system.

Testing and Certification

To verify the effectiveness of acoustic insulation solutions, it is essential to conduct appropriate testing and certification. This may include laboratory measurements of sound transmission loss, impact isolation, and airborne sound insulation in accordance with recognized standards, such as BS EN ISO 10140 and BS EN ISO 717. Partnering with accredited testing laboratories can help double-check that that the acoustic insulation meets or exceeds the required performance levels.

By staying up-to-date with the latest plumbing codes, noise control regulations, and testing standards, plumbing consultants can design and install commercial plumbing systems that not only function efficiently but also prioritize acoustic comfort for building occupants.

System Integration and Installation

Achieving optimal acoustic performance in commercial plumbing systems requires careful coordination between various trades and adherence to best practices during the installation process.

Coordination with Other Trades

Successful implementation of acoustic insulation solutions often involves close collaboration with other building professionals, such as architects, structural engineers, and HVAC contractors. Coordinating the integration of plumbing systems with other building elements, such as wall assemblies, floor structures, and ductwork, is crucial for ensuring that the overall acoustic performance is not compromised.

Installation Best Practices

Proper installation of acoustic insulation is essential for achieving the desired noise-reduction results. Plumbing technicians should follow manufacturer instructions and industry-accepted installation guidelines, ensuring a tight, friction-fit of insulation materials around pipes, fittings, and penetrations. Attention to sealing, overlap, and fastening details can help maintain the integrity of the acoustic barrier and prevent sound leakage.

Commissioning and Validation

Once the plumbing system and acoustic insulation are installed, it is important to conduct commissioning and validation tests to verify the overall acoustic performance. This may involve on-site measurements of sound pressure levels, vibration assessments, and listening tests to double-check that that the system meets the specified noise criteria. Any necessary adjustments or remedial actions can then be taken to optimize the acoustic insulation and achieve the desired level of noise control.

By integrating acoustic insulation considerations throughout the design, installation, and commissioning phases, plumbing consultants can deliver commercial plumbing systems that not only function effectively but also contribute to a more peaceful and comfortable indoor environment.

Maintenance and Performance Monitoring

To maintain the long-term acoustic performance of a commercial plumbing system, it is essential to establish a comprehensive maintenance and monitoring plan.

Periodic Inspections

Regular inspections of the plumbing system and its associated acoustic insulation are crucial. Plumbing professionals should check for any damage, deterioration, or gaps in the insulation that could compromise its noise-reduction capabilities. Addressing these issues promptly can help double-check that the continued effectiveness of the acoustic insulation.

Troubleshooting and Repairs

In the event of unexpected noise issues or changes in the acoustic performance of the plumbing system, it is essential to have a well-defined troubleshooting and repair process in place. This may involve identifying the root cause of the noise, whether it be due to changes in water flow, equipment malfunctions, or insulation failures, and then implementing appropriate remedial measures.

Ongoing Noise Mitigation

As building usage patterns or tenant requirements evolve over time, the acoustic insulation design may need to be re-evaluated and adjusted accordingly. Plumbing consultants should work closely with facility managers to monitor the system’s performance and implement any necessary modifications to maintain the desired noise levels within the commercial environment.

By establishing a comprehensive maintenance and performance monitoring protocol, plumbing professionals can double-check that that the acoustic insulation solutions they implement continue to deliver long-term benefits and contribute to the overall comfort and well-being of building occupants.

Emerging Technologies and Innovations

The field of commercial plumbing acoustics is constantly evolving, with the introduction of new materials, systems, and design approaches that aim to enhance noise control and occupant comfort.

Advanced Acoustic Insulation Materials

Innovative acoustic insulation materials, such as advanced mineral wool and high-performance cotton-based batts, are continually being developed to improve sound absorption, thermal performance, and ease of installation. These materials often feature enhanced density, thickness, and acoustic ratings that can provide superior noise-reduction capabilities compared to traditional insulation solutions.

Intelligent Plumbing Systems

The rise of smart building technologies is also beginning to influence the design of commercial plumbing systems. Intelligent control systems and monitoring sensors can now be integrated into plumbing networks to actively manage water flow, detect leaks, and even adjust pipe insulation or other acoustic treatment based on real-time noise levels. These advancements can lead to more efficient, adaptable, and quieter plumbing solutions.

Sustainable Design Approaches

Alongside the pursuit of improved acoustic performance, there is also a growing focus on sustainable design in the commercial plumbing industry. Plumbing consultants are increasingly incorporating eco-friendly materials, energy-efficient technologies, and circular economy principles into their acoustic insulation solutions to minimize the environmental impact and support long-term sustainability.

By staying abreast of the latest advancements in commercial plumbing acoustics, consultants can continue to deliver innovative, high-performance, and sustainable solutions that enhance the overall quality of the built environment for building owners, facility managers, and occupants alike.Statistic: Up to 30% reduction in water wastage observed in recent commercial plumbing upgrades